To determine the Turns Per Day (TPD) setting for a watch winder for your automatic watch, follow this expert procedure:

-

Identify Watch Model and Caliber

First, try to find the watch’s caliber or movement type, as manufacturers often specify the optimal winding parameters. The caliber number is sometimes on the back of the watch or on the dial, or you can ask the seller or check manufacturer resources. -

Start with Manual Winding

Manually wind your watch by turning the crown about 20-30 times to ensure it is fully powered before placing it on the winder. This is necessary because winders don’t work effectively on a stopped watch. -

Set Initial Winder Parameters

-

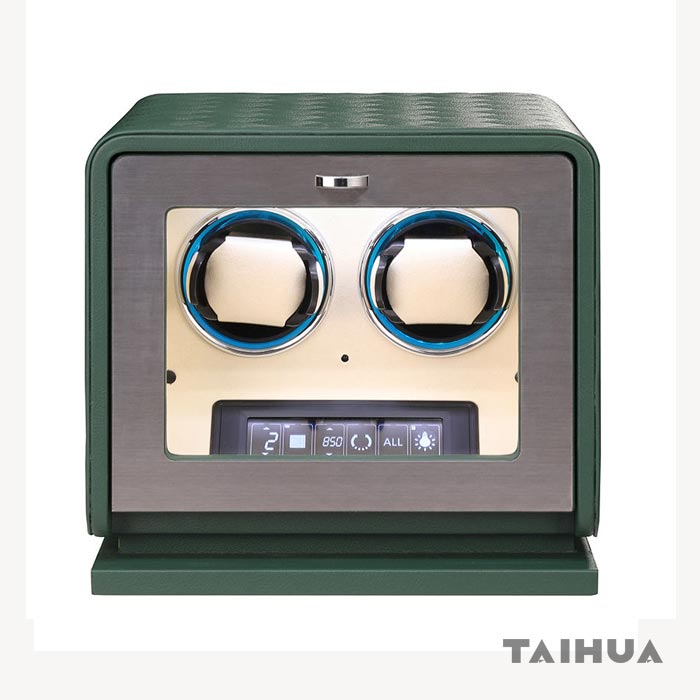

Set the winder to the lowest TPD setting available (usually around 650 TPD).

-

Choose bidirectional rotation mode (clockwise + counterclockwise) initially, as this covers most watches.

-

-

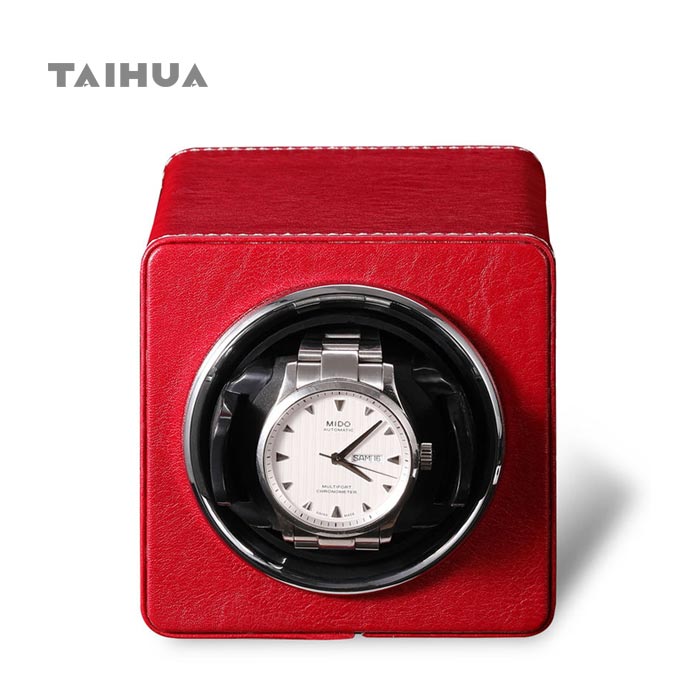

Test and Observe

Place the watch in the winder and let it run for about 48 hours. Check if the watch keeps accurate time during this period. Most automatic watches have about 40 hours of power reserve, so if the watch keeps time correctly after two days, the TPD setting is likely correct. -

Adjust TPD and Direction if Needed

-

If the watch runs slow or stops, increase the TPD setting step-by-step and repeat the test.

-

If timekeeping is still off, try changing the rotation direction to clockwise only or counterclockwise only, as some watches require a specific winding direction.

-

-

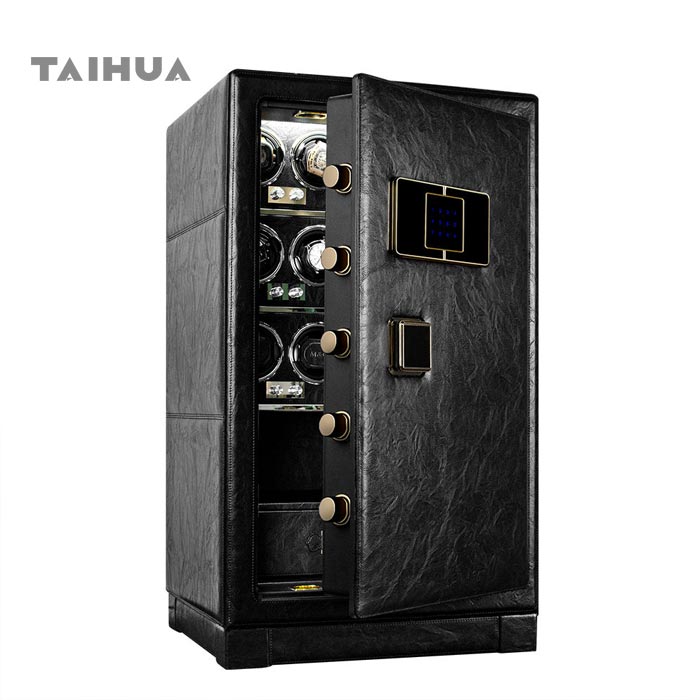

Confirm Optimal TPD

After finding a TPD and direction setting that keeps the watch running accurately without overwinding, this is your optimal setting. You can also verify by removing the watch from the winder and timing how long it runs before stopping; if it runs close to its full power reserve, the watch was fully wound.

Typical TPD Range

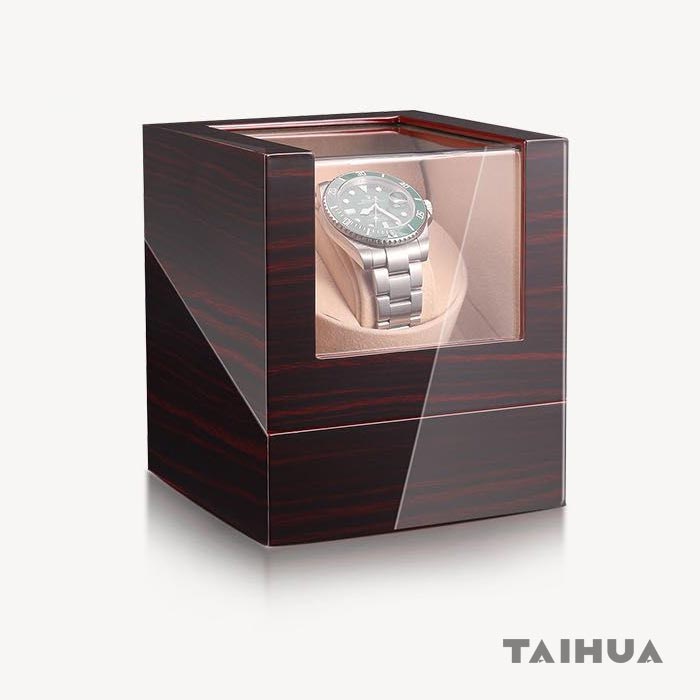

Most automatic watches require between 650 and 950 TPD, but some models (e.g., Rolex) may require around 650 TPD with bidirectional motion.

This trial-and-error method ensures your watch winder mimics natural wrist movement accurately, maintaining your watch’s power reserve and timekeeping precision without damage.