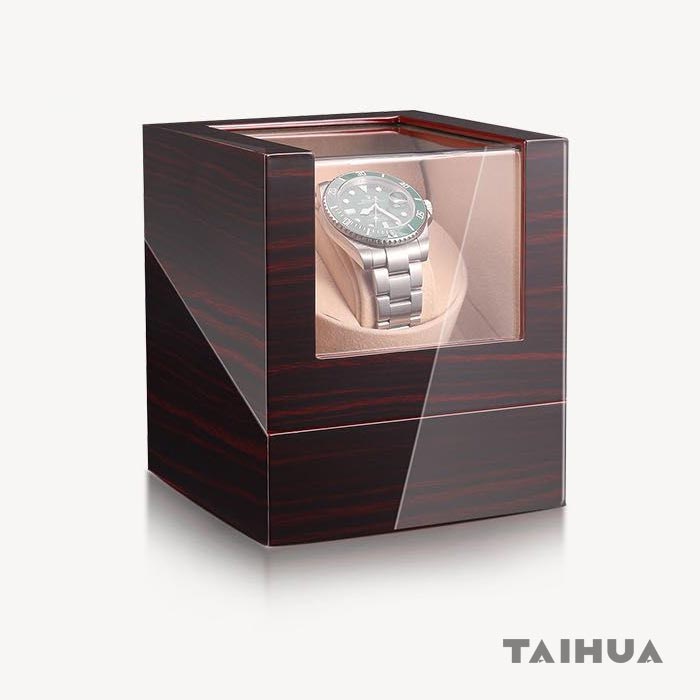

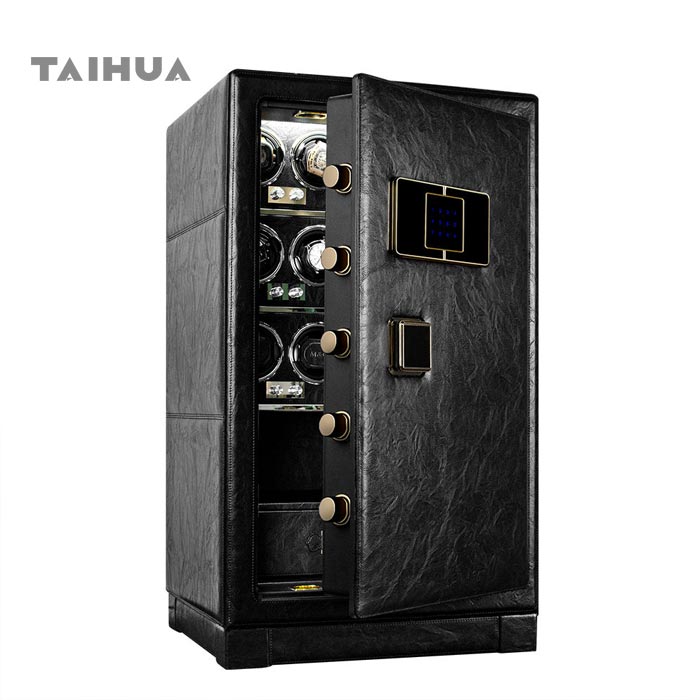

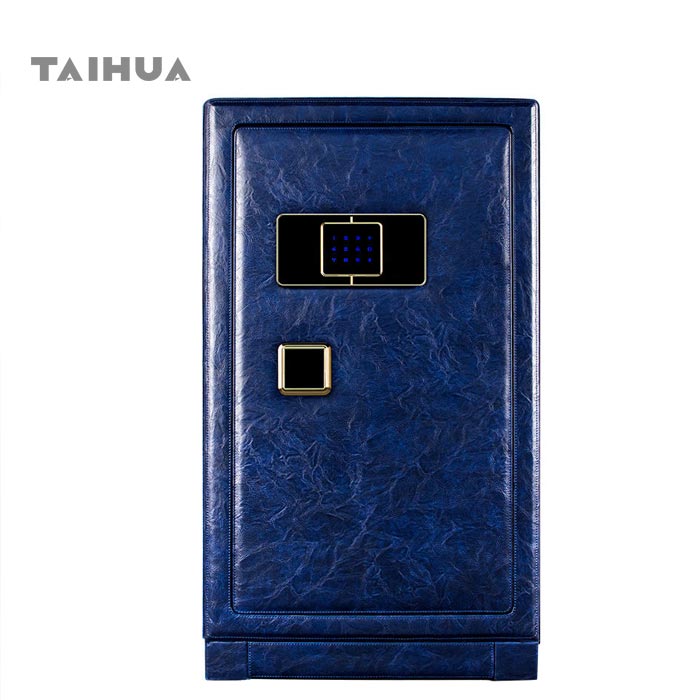

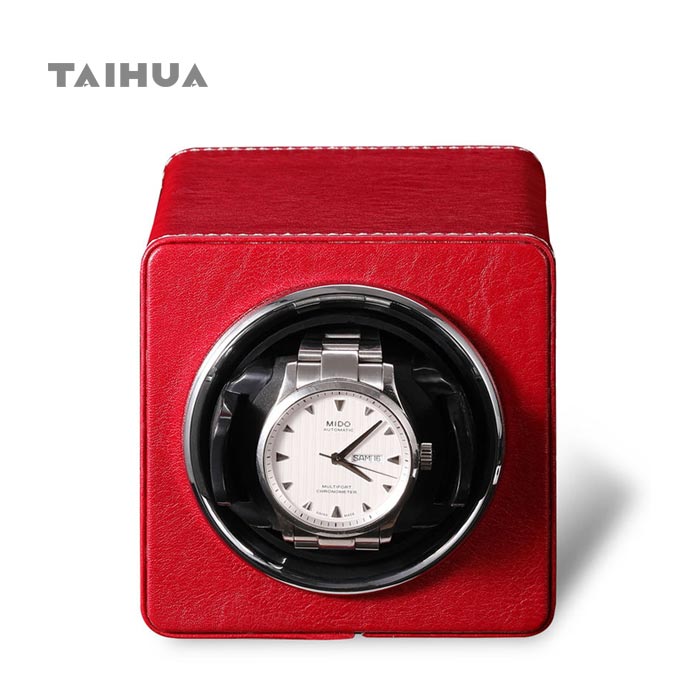

Watch winders can be expensive primarily due to several factors including high-quality materials, precise engineering, advanced features, durable and quiet motors, craftsmanship, and brand reputation. High-end watch winders often use premium materials such as wood, leather, and metal, and are handcrafted with attention to detail, which increases production costs compared to cheaper plastic models. These winders also come with sophisticated features like multi-directional rotation, adjustable turns per day, programmable timers, and additional functionalities like storage compartments and LCD displays, adding to their value and price.

Another significant cost factor is the motor quality, designed to be quiet, reliable, and long-lasting. High-end watch winder motors can operate for many years without maintenance, justifying higher prices. Furthermore, watch winders are specialty items produced in relatively low volumes, limiting economies of scale that typically lower costs in mass-produced goods. Established and prestigious brands also charge more due to their reputation, research, and innovation efforts in catering to serious watch collectors.

In summary, the expense of watch winders is linked to premium build quality, sophisticated technology and features, motor durability, limited production scale, and brand prestige, which together justify prices that range widely, with high-end winders costing much more than budget-friendly options.